Latest News

Key Test Data Summary for September 2025

The monthly comparisons of Total Lots, Bales and Weight tested for September 2025 compared with...Update on PIC Declaration Mandate

As previously advised, updates to the International Wool Textile Organisation (IWTO) Core Test...Key Test Data Summary for August 2025

The monthly comparisons of Total Lots, Bales and Weight tested for August 2025 compared with the...Key Test Data Summary for July 2025

The monthly comparisons of Total Lots, Bales and Weight tested for July 2025 compared with the...Key Services

- Wool Sampling

- Wool Testing

- Research & Development

- Certification & Reporting

- Equipment Manufacturing

- Certificate Verification

- AWTA Analytics (on-line Key Test Data)

- Subscribe to our newsletter

About Us

About Us

AWTA Raw Wool provides independent and objective wool certification services. AWTA Raw Wool's major services are sampling, testing and certifying the yield, fibre diameter, vegetable matter content, staple length and staple strength of greasy wool before it is sold.

Learn more about AWTA Wool Testing

Resources

Research papers

AWTA has achieved a world wide reputation for its research work and now has one of the largest teams of scientists working on raw wool metrology.

Our scientists regularly report on their work to the technical forums of the International Wool Textile Organisation (IWTO). Papers published by the Company's scientists are available for reference purposes and academic use.

Access to research publications produced by other organisations, when approval is provided, is also available.

Papers are grouped in the following categories, with pdf documents available for download and viewing.

Reviews and General Information

Wool Metrology - Past & Current Trends, Future Requirements![]()

Objective Measurements - more than pretty numbers![]()

Yield Testing

Review of IWTO-19 Appendix K Requirements - Measurement of Ash Content by NIRA![]()

Measurement of IWTO-19 Ash Content by NIR Analysis![]()

Use of NIR Technology for Predicting IWTO-19 Residual Ash in a Commercial Laboratory![]()

Use of NIR to Predict Residual Ash in the IWTO-19 Yield Test![]()

Use of NIR to Predict Residual Ash in the IWTO-19 Yield Test - 2nd trial![]()

A Review of the Range Checks Used When Testing for Wool Base in Accordance with IWTO-19![]()

Review of the Subsample Mass Limit for Yield Testing of Scoured Wool![]()

Evaluation of a Prototype Blender for Core Samples of Scoured or Carbonised Wool![]()

The Effect of Aqueous & Dual-Solvent Scouring on Wool Base Calculated According to IWTO-19![]()

Summary of the Trial Which Established The Equation For Calculating The Australian Carbonising Yield![]()

Fibre Diameter

In-shed Test Reports - Recommended Sampling Procedures![]()

Supplementary Report to the In-shed Sampling Group![]()

NSW In-shed Sampling Trials - Summary Report![]()

Implications of the CVD of Fibre Diameter on Measuring Mean Fibre Diameter![]()

Importance of the CVD of Fibre Diameter in Selecting Tops![]()

Fundamental Principles of Fibre Diameter Measurement![]()

The Measurement Precision & Evaluation of the Diameter Profiles of Single Wool Fibres![]()

Comparison Between Measurement of 'Dry' & 'Conditioned' Wool Samples in a Water Filled Laserscan![]()

What are the Limits to Wool Fibre Fineness Measurement![]()

Certification of Standard Deviation of Diameter of Raw Wool Measured by OFDA![]()

Calibrating Laserscan for Raw Wool Measurement & an Evaluation of an Alternative Transport Fluid![]()

Relationship b/w NZ Merino Fleece Measurement Produced at NZPAC Ltd & their Core Test Results![]()

Comparison of Histograms from OFDA, Projection Microscope & Laserscan for Wool Tops![]()

Measurement of Fineness on Superfine Wool - Effect of Revised Laserscan Calibration on Comparisons![]()

Fundamental Principles of Fibre Fineness Measurement - Airflow Instrument![]()

Effect of Fibre Medullation on Laserscan Diameter Measurement![]()

Variable Test Specimen Mass Airflow Round Trial![]()

Effect of Cell Snippet Position on Laserscan Diameter Measurement![]()

Comparison of Diameter Measurement Tech from Interwoollabs Inter Rnd Trials for Wool Tops![]()

Use of Variable Test Specimen Mass when Measuring Mean Fibre Diameter by Airflow![]()

Measurement of the Fineness of Superfine Wool - A Comparison of Airflow, Laserscan & OFDA![]()

The Effect of Between Fibre Coefficient of Variation on the Fibre Fineness Measured by Airflow![]()

Importance of CVD of Blends of Wool Tops when Measured by Airflow, Laserscan & OFDA![]()

Impact of Test Result Precision on On-Farm Decisions![]()

Using OFDA2000 & Fleecescan to Prepare Lots for Sale & Sheep Selection - A Case Study![]()

Fibre Curvature

Standardisation of Mean Fibre Curvature Using the Series 14 Calibration Top as a Reference![]()

Measuring Fibre Curvature - Key Issues![]()

Analysis of the Curvature of Wool Offered for Auction in Australia![]()

The Influence of Preparation Techniques on the Measurement of Fibre Curvature![]()

Fibre Curvature Morphometry & Measurement![]()

An Objective Technique for Measurement of Fibre Crimp Curvature - Part 1 - Metrology![]()

Evaluation of Alternative Methods for Fibre Curvature Measurement on NZ Wools![]()

Staple Measurements & Top Predictions

Final TEAM-1, TEAM-2 & TEAM-3 Reports![]()

Final Report on the Performance of the Style Instruments![]()

A Between-Instrument Comparison of Staple Crimp Frequency Measured by Crimp Meters![]()

Predicting Processing Results of Sale Lots - Part 1 - Performance of TEAM Hauteur Equations![]()

Predicting Processing Results of Sale Lots - Part 2 - Development of a Sale Lots Formula for Hauteur![]()

Predicting Processing Results of Sale Lots - Part 3 - Performance of TEAM Equations![]()

A Review of the Proposed TEAM-3 Formula for Predicting Hauteur![]()

TEAM-3 Processing Trial - Final Report![]()

TEAM-3 Processing Trial - November 2003 Update![]()

TEAM-3 Processing Trial - May 2003 Update![]()

TEAM-3 Progress Report - December 2002![]()

Preliminary Analysis of TEAM-3 Database![]()

The Examination of Decrimped Staple Length to

Deriving Additional Parameters from the Staple Force vs Extension Curve Measured by ATLAS![]()

Measurement of Staple Crimp Frequency Part 1 - Manual Measurements using the Crimp Gauge![]()

Measurement of Staple Crimp Frequency Part 2 - The Crimp Meter - Description![]()

Measurement of Staple Crimp Frequency Part 3 - The Crimp Meter - Initial Evaluation![]()

Differentiate Atypical Wool Types as a Potential Aid to Purchasing & Processing Prediction![]()

Report on Trials Evaluating Additional Measurements 1981-1988![]()

Industry Review of the TEAM Prediction Formulae![]()

Fleece Measurement

Sampling Variation Over A Fleece![]()

Colour of Raw Wool and Wool Sliver

Final Report of the IWTO Colour Working Group![]()

Report of the IWTO Colour Working Group![]()

International Rnd Trial Comparing Certified Tile Calibrations to Standard Wool Top Calibrations![]()

Calibration of Colour Instruments Using a Certified Tile & a Standard Wool Top![]()

Use of Regression Equations to Predict the Colour of Wool Using Ceramic Tile Calibration![]()

Performance of Various Calibrations When Measuring Certified Ceramic Colour Standards![]()

Scoured Wool

The Effect of Conditioning Time on Mean Fibre Diameter Results![]()

Review of the Subsample Mass Limit for Yield Testing of Scoured Wool![]()

Wool Sliver and Top

INTERWOOLLABS Report on Round Trials Completed in 2004![]()

A Review of the Distribution of Fibre Length in Tops![]()

Modelling of Length Distributions in the OFDA 4000![]()

Report on Equivalence Round Trials for the Almeter AL2000![]()

Foundations & Metrology of the Almeter Wool Fibre Length Measurement![]()

Application of a Raw Signal Filter on the Precision & Accuracy of the Almeter AL2000![]()

Investigations into the Repeatability & Precision of the Re-configured Almeter - AL2000![]()

Uniformity of Wool Characteristics

Processing of Classed Grower & Bulk Class Lots of Different Uniformity Index![]()

Prediction of Wool Preparation Category for Classed Fleece Lines using a Uniformity Index![]()

Assessing the Variability of Classed Fleece Lines Using a Uniformity Index![]()

Impact of Test Result Precision on On-Farm Decisions![]()

Wool Contamination

Definitions of Medullation Threshold Values used by Different Testing Methods![]()

The Precision of Dark & Medullated Fibre Testing of Noil![]()

Relationship btw Greasy & Processed Dark Fibre Contamination from DAMARA Crossbreds in Merino Wool![]()

Australian Wool Innovation 2004 Global Survey of Dark & Medullated Fibres![]()

Determination of the Contaminant Threshold Level for Medullated Fibres in Merino Wool Fabrics![]()

Residues of Pesticides in Australian Wool 2004-2005 - Results from AWI Survey![]()

Development of an Improved Test for Detection of Dark & Medullated Fibres in Presale Core Samples![]()

Update of Progress in Dark & Medullated Fibre Risk Project![]()

Development of a Quantified Risk Factor for Presence of Dark/Medullated Fibres in Aust Merino Wool![]()

Managing the Risk of Dark & or Medullated Fibre Contamination![]()

Merino Crossbreeding & Objectionable Sheep Fibres - The Problem & Potential Solution![]()

Exotic Sheep Breeds in Australia - A Status Report![]()

Fibre Medullation, Marketing & Management![]()

Wool Contamination - Pigmented & Heavily Medullated Fibres![]()

Dark Fibre Control in Sheep & Wool![]()

Dark Fibre Contamination in Wool - Its Prediction & Ramifications![]()

Preparation & Dark Fibre Contamination![]()

Formulae and Calculations

Industry Links

International Wool Textile Organisation (IWTO)

Australian Wool Innovation (AWI)

Australian Wool Industries Secretariat (AWIS) (Incorporates: Federation of Australian Wool Industries (FAWO), Australian Council of Wool Exporters and Processors (ACWEP) & Private Treaty Wool Merchants Australia (PTWMA))

National Council of Wool Selling Brokers of Australia (NCWSBA)

Australian Wool Exchange (AWEX)

Sheep Co-operative Research Centre (CFC)

Australian Wool Education Trust (AWET)

WoolProducers Australia

Australian Superfine Wool Growers Association (ASWGA)

Brochures and Handbooks

As part of its services to its clients and other interested parties, AWTA publishes brochures and various handbooks featuring information in regard to:

- AWTA's services

- Explanations/Reviews of current standard test methods

- Research & development of new test methods

- Other wool industry related matters

If printed, these publications are circulated, free of charge, to all addressees on our Mailing List. Otherwise they are available in electronic format on our web site.

Note that wool testing process and the company's operations change from time to time as a result of improvment to the process and these documents may not reflect some of these changes.

If you wish to be placed on our Mailing List and receive such publications please download the form below and complete the details in this form and return to AWTA at This email address is being protected from spambots. You need JavaScript enabled to view it.

Corporate Brochures

|

|

AWTA Ltd Corporate BrochureThis brochure provides an overview of AWTA Ltd as a whole and explains the roles of the various divisions which make-up the AWTA Group. AWTA is the largest wool testing organisation in the world. The AWTA group is comprised of three operating divisionsin Australia (AWTA Raw Wool, AWTA Product Testing and Agrifood Technology), its wholly owned subsidiary NZWTA and its joint venture, JinAo Testing Company. AWTA Ltd continues to expand its service offering into other agricultural and manufacturing markets where independent, high quality and high integrity testing is a vital part of the value chain. Download: AWTA Brochure |

|

|

Testing the WoolclipThis brochure has been designed to provide a comprehensive summary of the major services AWTA provides to the wool industry and descriptions of the processes used to achieve test results. The processes dicussed include:

Download: |

|

|

Laserscan TechnologyThis brochure contains a detailled discussion of the Sirolan Laserscan equipment used by AWTA for the determination of Mean Fibre Diameter. It reviews the IWTO methods that are followed during the measurement and certification process and explains in general terms how the equipment measures wool fibres. The main topics are:

Download: Laserscan Technology Brochure |

|

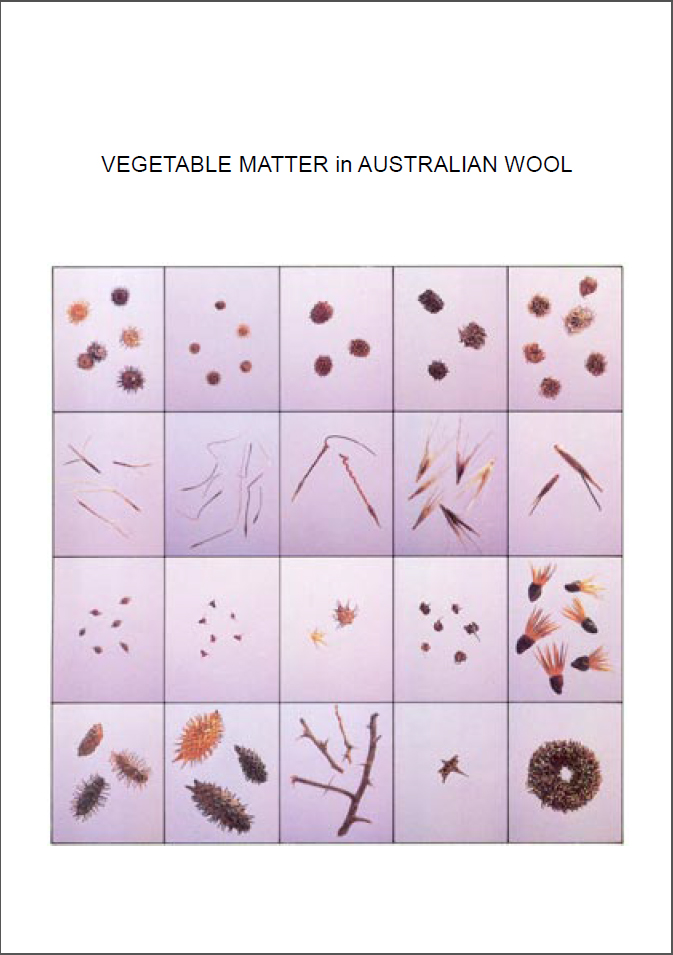

Vegetable Matter in Australian WoolThis booklet provides a useful reference for the identification of the major Vegetable Matter types which occur in Australian wool. The need for correct identification and standard nomenclature descriptions of vegetable matter is important and becomes even more so if the industry is to move to a system of selling based on measurement and standardised descriptions alone. The 3 broad categories of VM Type disucced in this handbook, coded simply B, S and H, are defined as follows:are sometimes questioned..

The VM types are described in this booklet as either B, S or H, as appropriate. Download the Handbook: Vegetable Matter in Australian Wool |

Wool Testing Handbook

Objective measurement is an integral part of the preparation, marketing and processing of Australian wool.

Nearly all Australian wool is tested for Yield, Vegetable Matter Base and Mean Fibre Diameter prior to sale and/or prior to export. An increasing proportion is also tested for Mean Staple Length and Mean Staple Strength. Scoured and carbonised wool is normally tested for Regain (moisture content). However, a significant number of scoured and carbonised lots are also tested for Yield and Mean Fibre Diameter.

This handbook is designed to provide members of the wool industry with details of the technical basis to Objective Measurement and the procedures for many of the common calculations. The information included is largely drawn from, or based upon, the relevant IWTO Test Methods and Regulations and Australian Standards.

This handbook is designed to provide members of the wool industry with details of the technical basis to Objective Measurement and the procedures for many of the common calculations. The information included is largely drawn from, or based upon, the relevant IWTO Test Methods and Regulations and Australian Standards.

The key features of the booklet are:

-

Calculation procedures and terminology are outlined for various Test Certificates

-

Sections on the precision of testing and retesting are included. These sections describe procedures available for improving the precision of a test result and the procedures followed by Test Houses when a retest is initiated

-

Core Test interyield conversion tables previously published in a separate booklet are included

-

A bareme for the calculation of theoretical HAUTEUR from raw test data according to the formula described in the report on trials evaluating additional measurements 1981-88, December 1988 (TEAM) has been included

This handbook, first published in September 1990 will not be reprinted. Copies of the latest issue of the handbook are still available and can be obtained from the nearest AWTA Raw Wool office.

Conversion Tables

The AWTA Wool Testing Handbook contains examples of calculations associated with IWTO Certificates, conversion tables for a number of Yields and tables for calculating Hauteur, based on the TEAM 2 Formula from Staple Measurements.

The conversion tables have been extracted from the Handbook and are available for download. These tables provide for conversions between yields as well as calculation of TEAM Hauteur from the Yield, Micron and Staple Measurement data.

A separate download is available that contains conversion tables and formulae for Scoured Yield at 16%, which were not included in the original publication.

Find our more:

New Conversion Tables for SCD 16![]()

Wool Trading Requirements

|

|

With the universal use of Test Certificates to define the specification of a wool trading contract, the accuracy and precision of the test results are sometimes questioned. This is particularly so as new measurements are introduced and there is no relaxation of commercial specifications in contracts. For the new generation of wool market traders, this is an update of earlier reports (reference 1,2,3) on this subject. It provides information to minimise the potential conflicts that can arise between the commercial wool trading requirements and the technical limitations of IWTO Test Methods and Regulations. It discusses issues such as accuracy, bias and precision, what factors affect these charateristics and how they are relevent to wool testing. The relationship between check-tests and re-tests is also explained. Download: Wool Trading Requirements |

|

|

|

Annual Reviews

|

The Annual Review is a report by the Directors to the Member Guarantors on the performance of the Company over the previous financial year. It includes a full financial statement for the financial year under review. The Annual General Meeting of Member Guarantors is usually in October. The Annual Review is distributed to the Members and, if accepted, it is then available for general distribution. Annual Reviews available for download: |

|

_____________________________________________________________________________________________

| Complete Annual Review |

Directors' Report & Financial Statements |

|

AWTA Ltd Annual Review 2023-2024 AWTA Ltd Annual Review 2022-2023 AWTA Ltd Annual Review 2021-2022 AWTA Ltd Annual Review 2020-2021 AWTA Ltd Annual Review 2019-2020 AWTA Ltd Annual Review 2018-2019 |

|